Project Success Stories

Discover detailed accounts of how our custom automation, machine modifications, and precision solutions transformed client performance and quality.

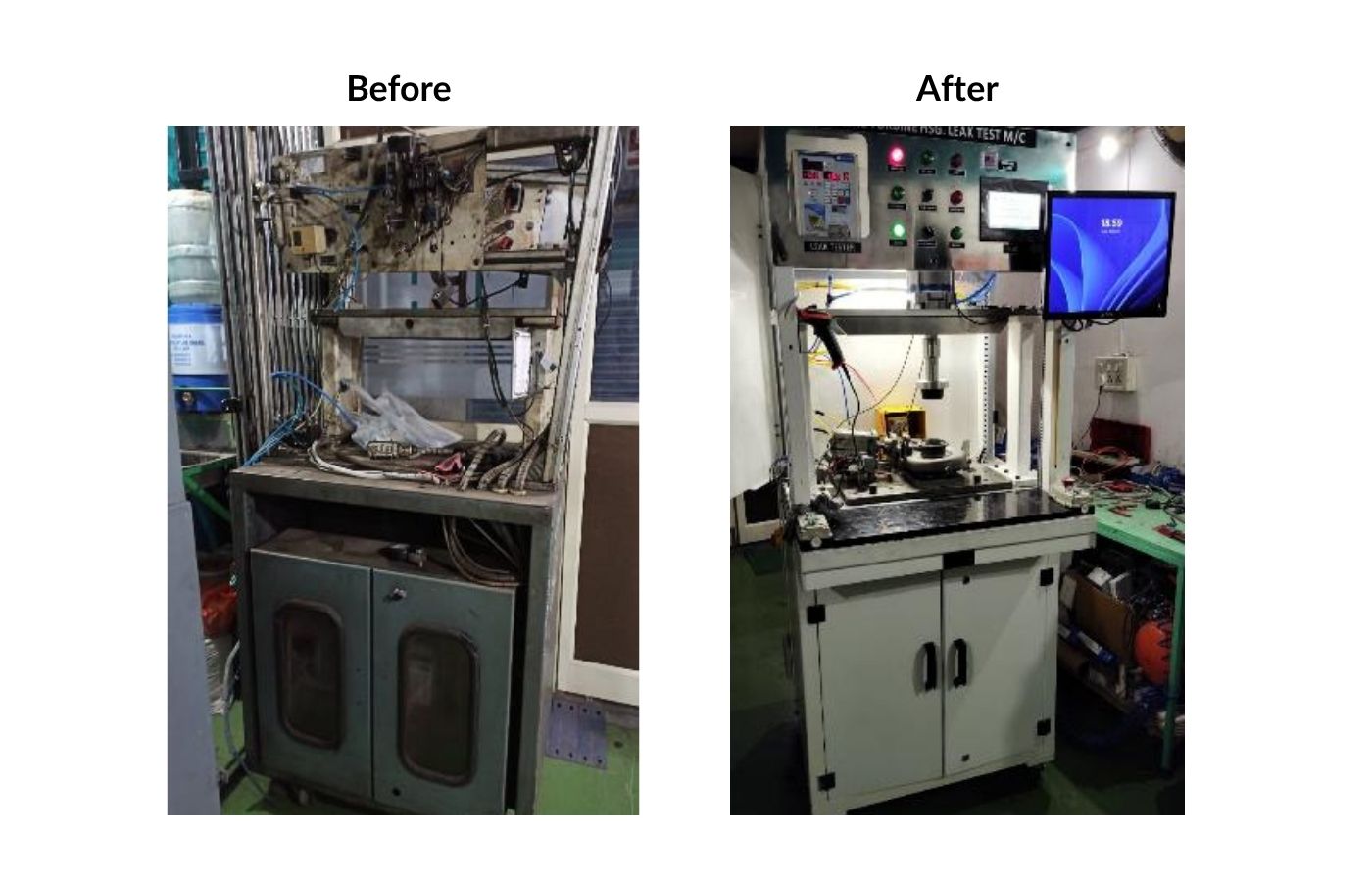

Leak Test Machine Modernization

Challenge:

Existing machine delivered inconsistent leak test results due to outdated controls and mechanical systems.

Solution:

Upgraded PLC and leak rate control, modified fixture and pneumatic systems, and integrated comprehensive poka-yoke features to ensure process reliability.

Result:

- Improved cycle time by 40%.

- Achieved 2 cc/min leak detection sensitivity.

- Reduced operator dependency and enhanced test accuracy.

- Increased existing machine life after modifications with good operating conditions and update all latest modifications.

Automation in Bush/Bearing Press Machines

Challenge:

Manual press operations led to inconsistent depth, operator fatigue, excess manpower, missed operations, and high rejection rates.

Solution:

Implemented a multi-station automated assembly line with interlinked press machines, integrated sensors, and poka-yoke systems to ensure consistent and reliable operation.

Result:

- 50% improvement in cycle time.

- Eliminated missed operations.

- Reduced manpower to a single operator.

- Achieved zero rejection through full automation.

Error-Proofing with Volute Blockage Detection

Challenge:

Internal sand core blockages in cast volute housings caused field failures.

Solution:

Engineered blockage detection using air pressure drop measurement & custom fixturing.

Result:

- Zero defects after implementation.

- Clear pass/fail indication.

- Ensured total inspection reliability.